About Is die casting used in photovoltaic cells

To make perovskite solar cells an industrially relevant technology large area deposition techniques are needed and one of the most promising is slot-die coating. This review article details the progress r.

The remarkable opto-electronic properties of lead halide perovskites coupled with the.

The perovskite layer is the most important layer in the perovskite solar cell device stack, to this end it is vital to have defect free films with large grain size, crystal phase purit.

Recently, 2D perovskites have gained interest due to improved lifetime compared to 3D perovskites [56]. 2D perovskites are typically prepared by introducing a large organic mol.

Although it is important to perfect the deposition of the perovskite layer, it is also vital to achieve the same with charge transport layers. Defects in the coatings can be detr.

In PSCs transparent conductive oxides (TCO) have been the preferred choice for transparent electrode (hereafter referred as bottom electrode) mainly because of its good electri.

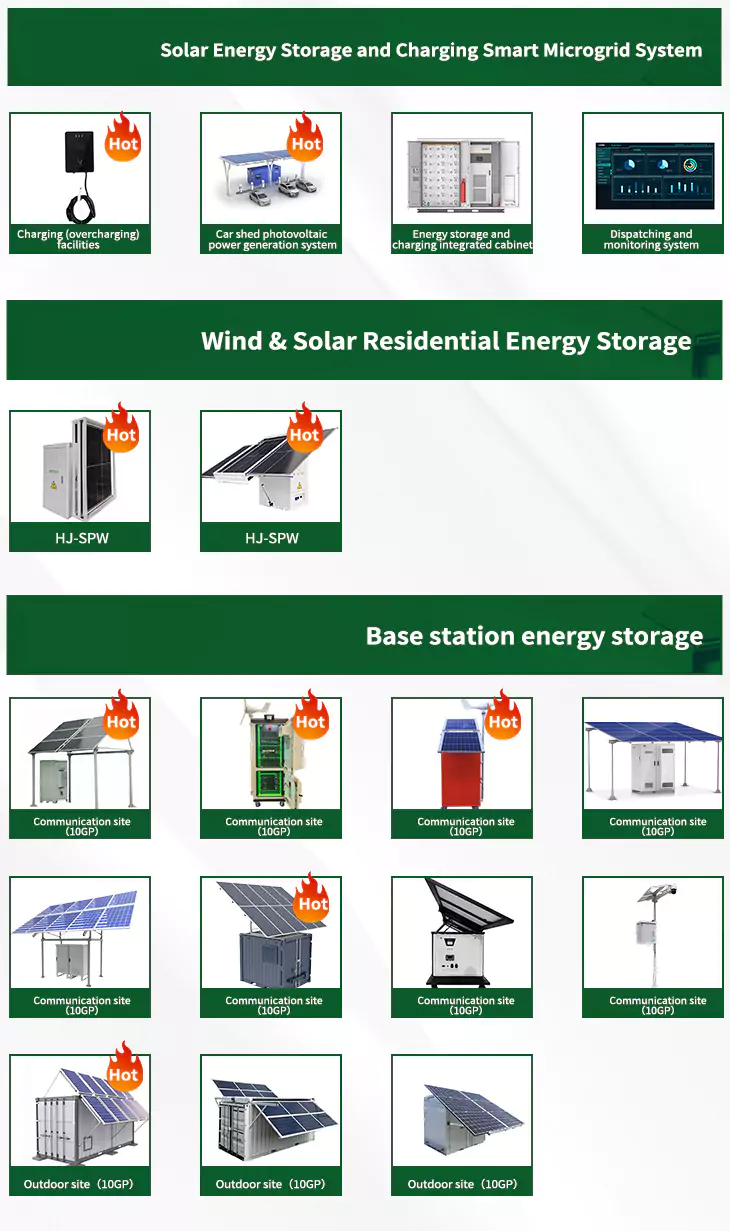

As the photovoltaic (PV) industry continues to evolve, advancements in die casting used in photovoltaic cells have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient die casting used in photovoltaic cells for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various die casting used in photovoltaic cells featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Related Contents

- Die casting machine energy storage timeout

- Stylish photovoltaic cells

- Photovoltaic cells convert

- Stringer machine for photovoltaic cells

- Efficiency photovoltaic cells

- Application of photovoltaic cells

- Transparent photovoltaic cells efficiency

- Photovoltaic cells for dummies

- Materials used in solar photovoltaic

- What are photovoltaic panels used for

- Organic photovoltaic cells history principle and techniques

- Photovoltaic cells biomimicry